A 3D-printed miniature filament choice is an important decision you should consider. Plastic filament is available in many forms, each with advantages and disadvantages. At one time or another, you’ve probably seen your friends or colleagues work with plastic filament. The filament is one of the most versatile materials available for 3D printing. This article will focus on the most common 3d printer filament for miniature options. In addition, you will learn which ones are best suited to your project. You should also know a few other things about filament, including how to pick the right one. If you are considering upgrading your 3D Printer, see our guide to buying the Best 3D Printer for Miniatures.

Polylactic Acid (PLA)

Polylactic acid is a type of polymer with a larger molecular structure. This makes it an ideal material for 3D-printed miniatures. Polylactic acid was first developed for use in biomedical research. Tissue engineering, in particular, is biodegradable. As a result, it won’t harm the environment at all during its breakdown.

This material is non-toxic. Due to this, it has been used in various industries and manufacturing processes. It has been used in polymers for multiple purposes in the past. For example, in the production of Teflon-coated medical equipment.

The material has also been successfully used to produce plastic parts for aerospace applications. Due to the wide range of applications for Polylactic Acid, it is now used in a wide range of 3D printing applications.

Properties

- High strength | Low flexibility | Medium durability

- Ease of use

- Temperature for printing: 180–230°

- The temperature of the print bed: 20–60°C (optional)

- Minimal shrinkage/warping

- Insoluble.

- The product is food safe as long as instructions are followed.

- Easy to print

- Available in a variety of colors and patterns

- Biodegradable.

Models and toys with textured surfaces are widespread, giving them a unique appearance. Polylactic acid has gained exponential popularity as a filament for miniatures. Manufacturers of model kits are now producing more intricate and detailed miniatures as the use of this type of PLA filament for representations has spread.

In addition to the automobile and airplane models, it is now applied to a wide range of 3D-printed products. Polylactic acid is still expensive compared to other filaments. It has grown in popularity and is often the best filament for minis.

Acrylonitrile Butadiene Styrene (ABS)

ABS is less standard than PL. Despite this, ABS is a highly versatile polymer well-suited for many applications. In addition, this polymer does not react with any liquid so it can be used in various moving and fixed parts.

This material can be used to construct any part. You can build any vehicle, weapon, house, or industrial machinery. Using this material has many advantages. Because of this, manufacturers prefer to work with this material.

For precision machining, this material can be used in many ways. For example, tolerance heating, hot forming, grinding, routing, drilling, and other sheet metal work. This material can be shaped into any desired shape using simple computer numerical controls.

In this way, excellent products can be produced at a reasonable price. You can also mold the material into any shape by varying its pressure. As a result, superior quality products are made.

Properties

- High strength | medium flexibility | high durability

- The difficulty of application: medium

- Temperature for printing: 210–250°C

- The temperature of the print bed: is 80–110°C

- Significant shrinkage/warping

- Esters, ketones, and acetone can be soluble in them.

- It is not food safe

- Durable

Injection mold rubber is a prevalent form of ABS. This material comes in various complex conditions, such as rubber tires and tubes, rubber mats, and many others. It is also used to construct parts of boats, phone cases, and plastic parts for toys.

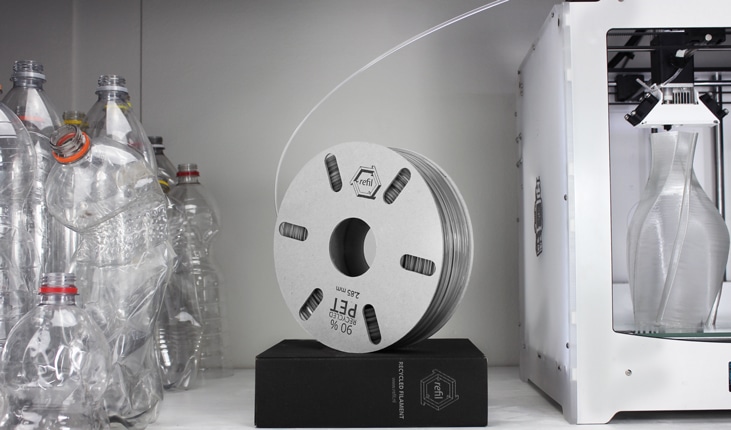

Polyethylene Terephthalate (PET)

Thermoplastic polymers, like PET, demonstrate many beneficial characteristics when working with plastic. The printing industry uses it extensively. Because it is a strong polymer, it can withstand high temperatures and is non-toxic.

Polyethylene terephthalate is also very flexible. Because it can be applied in various applications, this has its benefits. Furthermore, it is resistant to solvents and will not change color when used. As a result, it is ideal for use in protective coatings.

Polyethylene terephthalate is inherently cleaner. In addition, it is less brittle and, most importantly, more accessible to print than its basic form as a 3D printing material. As a result, PET is often seen as a suitable compromise between ABS and PLA, two other widely used kinds of 3D printer filament. It is more flexible and durable than PLA and is simpler to print than ABS.

This material is durable and can handle high temperatures and pressures without breaking. Additionally, it is suitable for high temperatures, so even when your model is melting, the extruder will not melt it. In addition, terephthalate is resistant to acids and will not change color when exposed. Lastly, it is very dense. Thus, plastics can be packed tightly compared to traditional plastics.

Properties:

- High Strength| Medium Flexibility | High Durability

- Ease of use

- Temperature for printing: 220–250°C

- The temperature of the print bed: 50–75°C

- Minimal shrinkage/warping

- Insoluble.

- It is relatively food safe, provided you follow the manufacturer’s instructions.

There are three considerations to keep in mind when using PETG in 3D printers for miniatures:

- PET absorbs moisture from the air and is hygroscopic. A material’s printability is adversely affected by this. Maintaining an excellent, dry location and, if needed, drying the 3D printer material before use is crucial.

- When printed, PET is sticky. Hence it is not suitable as a support structure but an excellent material for adhesion to layers in 3D printers.

- PET scratches more readily than ABS but is not as brittle.

A large number of other products can also be made with terephthalate. This allows it to be used for various industrial applications, from tools to furniture. Furthermore, polyethylene is very versatile so we can use it in many ways. Due to its versatility, it is often used when designing 3D-printed miniatures.

Thermoplastic Elastomers (TPE)

Polymers with rubber-like properties, TPEs are flexible and long-lasting. TPE is widely used to manufacture automobile components, home appliances, and medical supplies. TPE is ideal for 3D-printed plastic miniatures since it allows plastics manufacturers to produce high-quality models.

Manufacturers can make a more durable and wear-resistant plastic by using this material. The designs can also create intricate details that would otherwise not be possible with regular types of plastic.

In some areas, this material can also expand. Therefore, it can provide an aesthetically pleasing environment that is also durable. This material lets you get the most out of your plastics without concern about their longevity. Several companies in the industry have proved this.

Furthermore, TPE will not easily crack or break, so it is a good choice for 3D Printed Plastic Miniatures. If you use regular plastics in your creations, this problem is common. Furthermore, this material is safe for the little ones to use.

Properties:

- Medium strength | high flexibility | high durability

- Medium (TPE, TPC); Low (TPE, TPC) Difficulty to use (TPU)

- Temperature for printing: 210–230°C

- The temperature of the print bed: 30–60°C (but not needed)

- Minimal shrinkage/warping

- It is insoluble.

- It is not food safe.

By using thermoplastic elastomers, 3d printing can get quality figurines in a shorter amount of time. Additionally, thermoplastic Elastomers are resistant to changes in temperature, as well as high compression and expansion capacity. Small plastic parts can easily be made with it, allowing for easy handling.

In addition, it has a high permeability level, making it easy to form almost any shape. Increasingly, thermoplastic elastomers are used for a variety of applications. These thermoplastic elastomers are available at most of the leading plastic manufacturers worldwide. e EPDM, ELF, GPF, PNF, PTI, HIP, and PT are standard thermoplastic elastomers.

Conclusion

If you choose the suitable filament for your model, your 3D-printed miniatures will look great and run smoothly. In general, the best filament for printing miniatures is the kind that can produce tiny droplets of filament on its roll. The larger the droplets of filament, the finer the piece becomes. That’s also why 3D-printed miniatures are best printed using droplets of filament that are small in size. There are different kinds of filament for 3d printing minis. However, those that use standard filaments are the most popular. Examining the other options will make you decide which is right for you. The outcome will be significantly affected by this factor.